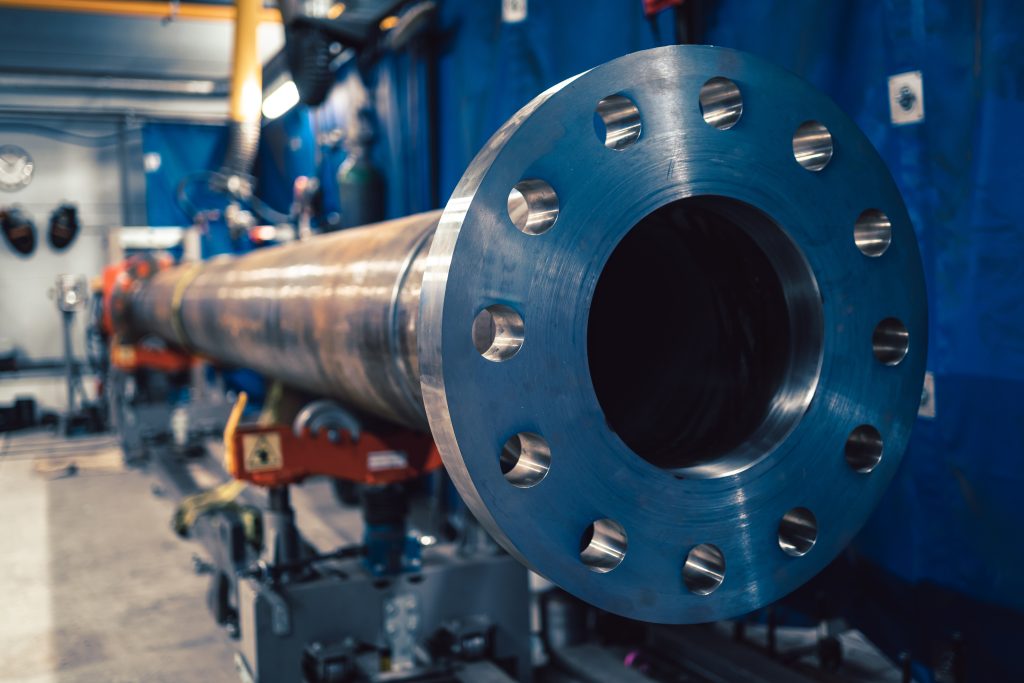

Did you know HL-Hydraulics also manufactures single cylinders and small series?

When it comes to hydraulic cylinders, our aim is to be a full-service partner—not only for repairs and refurbishments but also for custom manufacturing.

Over the years, we’ve had the opportunity to solve a wide range of hydraulic cylinder challenges, many of which have gone beyond standard repairs.

Sometimes the need for a single cylinder arises unexpectedly. Other times, it’s a deliberate decision, often driven by cost considerations or unique machinery requirements. Typically, the need for a new cylinder comes up when an older cylinder in a machine needs replacing, or when a customer is building something new or modernising existing equipment.

To clarify why customers come to us for custom-built cylinders, we’ve put together a summary of the most common scenarios we’ve encountered.

1. Economic reasons: While our first approach is always to repair and restore the existing cylinder, there are situations where repair is no longer economically viable. In such cases, manufacturing a new cylinder may be the more cost-effective solution.

For example, if an old cylinder contains outdated or hard-to-source components, and locating those parts would require considerable time, it may be more cost-effective to manufacture a new cylinder using readily available, modern components. Similarly, if the cylinder is in poor condition with extensive internal damage, the scale of repairs required may make a new build the more practical option.

There are also cases where customers request an identical replacement for a cylinder currently in service—often for spare part purposes. In these situations, we measure and document the existing unit and manufacture a matching hydraulic cylinder. Having a spare on hand increases production reliability, allowing planned maintenance or rapid replacement in the event of failure, minimizing downtime and disruption.

In some cases, the delivery time for a replacement cylinder can be long, which may significantly extend production downtime and result in substantial financial losses. In these situations, manufacturing a replacement cylinder in-house can be the more economical choice. HL-Hydraulics offers highly competitive lead times for new cylinder production.

2. Improved performance – In some cases, the specifications of an existing cylinder no longer meet the demands of the machine or application. When performance, durability, or efficiency needs to be improved, it can be worthwhile to replace the old cylinder with a newly designed one that better suits the operating conditions or delivers enhanced functionality.

A customer may want a cylinder with enhanced features compared to the standard option. This could mean a stronger structure, easier maintenance, or improved reliability. For example, a cylinder with a hardened rod might be preferred for demanding conditions. In such cases, modifying an old cylinder to meet these new requirements can often be surprisingly costly—making it more practical and cost-effective to design and build a new cylinder from scratch.

In some situations, customers are looking to fully customise a hydraulic cylinder to meet specific operational needs. This might include added sensors, upgraded materials, or enhanced functionality. Manufacturing a new cylinder allows for a flexible process—starting from design—so that every requirement can be addressed from the outset.

3. Spare parts unavailable – In some cases, manufacturing a new cylinder is the only viable option to get a machine back up and running. When original spare parts are no longer available—due to discontinued models, supplier issues, or obsolete designs—it may be impossible to repair the existing cylinder. In these situations, producing a custom replacement is the most efficient way to restore the equipment’s functionality and avoid extended downtime.

Sometimes a replacement cylinder simply isn’t available. The original manufacturer may have discontinued the part, and no alternative suppliers offer a compatible model. In some cases—particularly with specialised or custom-built cylinders—the component may never have been available as a standalone spare part.

When this happens, manufacturing a new cylinder becomes the only practical way to restore the machine and keep operations running.

4. A new single cylinder or small batch is sometimes simply the best solution

In situations where a customer is designing a new machine or modernising an older one, expert support and consultation are often essential—especially when a suitable hydraulic cylinder is needed. In these cases, the process starts from a clean slate, using the customer’s specified parameters as a foundation. From there, we ensure the cylinder—or cylinders—deliver safe, reliable performance tailored to the intended use.

Every hydraulic cylinder we manufacture is custom-built. Whatever the requirement, we work closely with the customer to find the solution that best meets their needs—both technically and practically.

What is the cost?

The price of a custom-manufactured hydraulic cylinder depends on several factors, and each project receives a tailored quote. There’s no fixed price tag, but below is an overview of what typically affects the final cost.

Cylinder size plays a key role, as it directly impacts the volume of materials required. Thanks to HL-Hydraulics’ extensive partner network, we can offer highly competitive material pricing—meaning you won’t be paying over the odds for raw materials.

Design approach is another factor. We always aim for cost-efficient, production-friendly designs. During the design phase, we consider how to incorporate standard-size seals, bearings, and other components wherever possible, as long as they meet the intended application.

Cylinder features are one of the biggest price drivers. The more specialized the materials—such as acid-resistant stainless steel—or the more advanced the features—like linear sensors or other monitoring tools—the higher the cost. Surface treatment requirements can also have an impact, especially if enhanced coatings or finishes are specified.

Delivery timeframe can influence the price as well. If a customer needs a cylinder significantly faster than standard lead times allow, expedited production may incur additional costs—especially if overtime is needed. That said, HL-Hydraulics always aims for fast turnaround, and our supplier network helps us maintain excellent delivery performance. We’re transparent about pricing—if a rush fee is necessary, it’s clearly communicated during the quoting process. And if the situation is truly urgent, we’ll do everything we can to assist.

Finally, delivery time itself is primarily affected by the availability of materials and purchased components. For most standard items, availability is strong. However, if the cylinder includes measurement sensors or specific valves, these components may have longer lead times, which can extend the overall schedule.

How is a custom hydraulic cylinder designed?

When designing a hydraulic cylinder for a customer, we can start from a few different points.

If the customer has an existing model, we can base the design on technical drawings or by measuring the original cylinder directly. The most accurate and efficient method is to use 3D scanning—a service we offer at HL-Hydraulics. Once the cylinder is scanned and modelled, we can either build an exact replica or modify it to meet the customer’s updated requirements. Common modifications include upgrading seals to more modern options, improving end cushioning for better performance, or reinforcing known weak points such as rod eyes or other parts of the structure.

Alternatively, the cylinder can be fully designed by HL-Hydraulics from the ground up, based on the customer’s specifications. To do this, we usually need details like the cylinder’s outer dimensions, installation length, stroke, movement speed, force requirements, preferred materials, and information about the operating environment such as temperature. That said, we can also get started with very limited input. Our team has years of design experience and draws on proven solutions tailored to different applications. Before anything moves into production, the final design is always reviewed and approved by the customer.

Do you have a need for a new spare cylinder—or a custom-built unit for a specific project? If so, you can submit a contact request below, or share the basic details of the cylinder you’re looking for. We’ll be in touch shortly to discuss the next steps.