This week’s blog post takes a look at the disassembly stage of a real-life cylinder repair case. There are many ways to open a cylinder—here’s one of them.

Starting Point

A hydraulic cylinder on an excavator had developed a crack in the tube and jammed in a position that left the machine inoperable. Fortunately, the customer was able to make an emergency patch, allowing the machine to be moved to a workshop and the cylinder sent to us for repair. Once it arrived, we drained the oil and mapped out a plan of attack.

The strategy: cut the cylinder tube just behind the piston, allowing us to salvage as many components as possible for reuse.

Why not disassemble it the “normal” way?

Forcing the cylinder apart through the guide end would risk serious damage to the rod, piston, dampers, or other internal parts. In cases like this, heat expansion from welding can also distort the inside of the tube, making removal even more difficult and potentially causing further damage.

Since the tube is already beyond repair and won’t be reused, the cleanest and safest option is to cut it open behind the piston—using a saw.

Opening and Removing the Piston

After cutting the tube, we were able to access the piston nut. At this stage, we also inspected the end of the cylinder tube to ensure it was still in usable condition and could be reused in the repair.

The piston nut comes off easily on the bench with the correct wrench. It was fastened on quite firmly, so manual removal wouldn’t have been possible.

The piston nut can be unscrewed by hand for the final turns, allowing access to the piston itself.

Next, we tap the tube manually toward the rod eye, which allows the piston to come free.

Remember: it’s always best to use copper tools during disassembly to protect the cylinder components and keep them in good condition.

With the piston freed from the tube, we were able to inspect its condition. Although it had taken a few knocks, it’s still in good enough shape to be refurbished and put back into use.

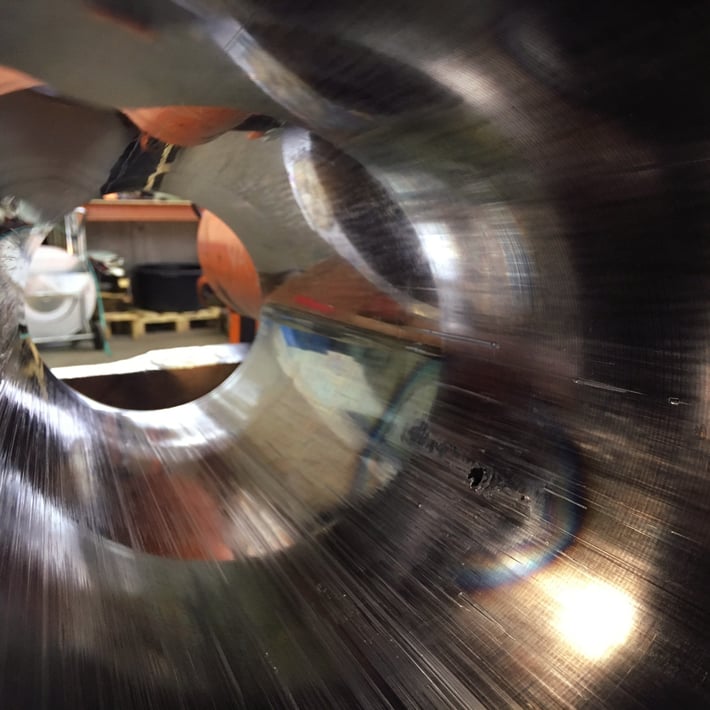

Here’s a photo from inside the tube, showing exactly why we didn’t open it using traditional methods. The blue ring indicates heat-induced changes, and at this point the tube has deformed to such an extent that the diameter has narrowed—preventing the piston from moving.

The cylinder repair continues with the installation of a new tube. From the original, we’re able to reuse the end cap, gland, and damper components. The piston will be repaired, and all seals replaced. The rod remained in good condition, so it can be reused as-is.

In every repair, we aim to salvage as many components as possible—provided they can be restored with a reasonable amount of work.

Hydraulic cylinder repair cases vary greatly, and this is just one example. We’ll be sharing more interesting repair stories in the future.